Mazda CX-5 Owners Manual: Manual Transaxle Operation

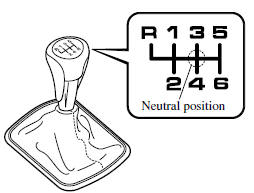

Manual Transaxle Shift Pattern

The shift pattern of the transaxle is conventional, as shown.

Depress the clutch pedal all the way down while shifting; then release it slowly.

Your vehicle is equipped with a device to prevent shifting to R (reverse) by mistake.

Push the shift lever downward and shift to R.

WARNING

Do not use sudden engine braking on slippery road surfaces or at high speeds:

Shifting down while driving on wet, snowy, or frozen roads, or while driving at high speeds causes sudden engine braking, which is dangerous.

The sudden change in tire speed could cause the tires to skid. This could lead to loss of vehicle control and an accident.

Be sure to leave the shift lever in 1 or R position and set the parking brake when leaving the vehicle unattended: Otherwise the vehicle could move and cause an accident.

CAUTION

● Keep your foot off the clutch pedal except when shifting gears. Also, do not use the clutch to hold the vehicle on an upgrade. Riding the clutch will cause needless clutch wear and damage.

● Do not apply any excessive lateral force to the gear lever when changing from 5th to 4th gear.

This could lead to the accidental selection of 2nd gear, which can result in damage to the transaxle.

● Make sure the vehicle comes to a complete stop before shifting to R.

Shifting to R while the vehicle is still moving may damage the transaxle.

NOTE

If shifting to R is difficult, shift back into neutral, release the clutch pedal, and try again.

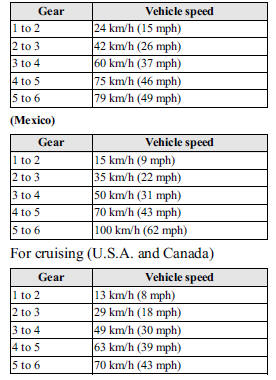

Recommendations for Shifting

Upshifting

For normal acceleration, we recommend these shift points.

(U.S.A. and Canada)

Downshifting

When you must slow down in heavy traffic or on a steep upgrade

, downshift before the engine starts to overwork. This reduces the chance of stalling and gives better acceleration when you need more speed.

On a steep downgrade

, downshifting helps maintain safe speed and prolongs brake life.

Transaxle

Transaxle

...

Automatic Transaxle Controls

Automatic Transaxle Controls

Various Lockouts:

NOTE

The Sport AT has an option that is not included in the traditional automatic

transaxle giving the driver the option of selecting each gear instead of leaving

it to the ...

Other materials:

Drive Belt Inspection [Skyactiv G 2.0]

Generator Drive Belt

NOTE:

The generator drive belt deflection/tension inspection is not necessary with

the adoption of the drive belt auto tensioner.

1. Verify that the indicator part of the cast hexagon on the drive belt auto

tensioner is within the normal range.

If ...

Door Ajar Warning Light

Purpose

The door-ajar warning light notifies the driver that any door or the liftgate

is open.

Function

When the instrument cluster receives any of the following signals sent from

the rear body control module (RBCM) via the CAN signal, the door-ajar warning

light illumin ...

Cabin Side Frame Straight Line Dimensions [Dimensions]

Point symbol

Designation

Hole diameter or bolt or nut size mm {in}

A

Front side frame outer datum hole

?12 {0.47}

B

Front fender panel installation hole

?10 {0.39}

...